- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 106

- Place of Origin: Jinan,Shandong

- Brand Name: dingdian1

- Model Number: LT-6020

- Weight: 12000.000 kg

- :

- :

- :

- :

- :

- :

- :

- :

- :

- :

Overview

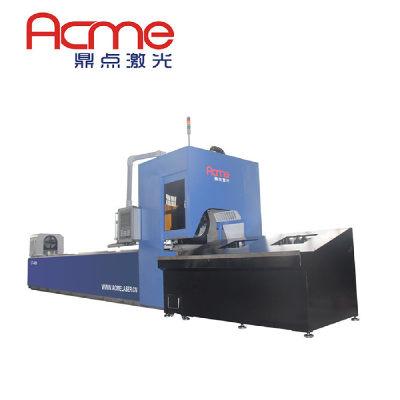

The fast-speed full automatic Pipe Tube Laser Cutting Machine of ACME•LASERLAB can cut circle tubes, rectangular tubes and other irregular-shaped tubes. The new tube laser processing production line not only implements automatic production, but also breaks through the limitation of plane cutting. Achieved multi-dimensional cutting, it is the optimal choice for metal tube laser cutting.

FEATURES

Automatic set-up and run

Round, rectangular, square and other profiles are standard

Standard components for easy service and maintenance

Random standard length

500W-4000W IPG resonator

Lantek programming software

WHAT MCAN DO

High Precision Cutting and Processing Carbon steel, Stainless steel,

Aluminium, Brass, Copper and other metal material tubes.

Round, Rectangular, Square, Oval and all kinds tube shapes.

MACHINE ADVANTAGE

16-25mm whole steel plate weld strong machine bed made by FINCM. Milled by COLGAR, Aging and Heat treatment. More Stable and Reliable than pipe weld machine bed which other suppliers normal use.

Self-centering Collet Chuck

The collet chucks position and hold your tubes in place without damaging the materials. The self-centering clamping system with continuous sensor monitoring adapts to every tube geometry.

A Constant View of the Machining Process

With the large window, the machining process of automatic tube laser is perfectly visible.

Automatic Stepped Rollers

The step rollers support the tubes while also moving them sideways, and adjust automatically to various diameters.

Germany PA8000 Control System

The original imported control system is very stable and reliable. With Acme design of panel surface, it is easy to face any direction that is convenient for the operator.

Automatic or manual loading system from the back of machine--PATENT DESIGN

15-20s loading time, more faster than 60s side loading which other supplier use.

More Details Please Contact: Eric Liu WeChat/WhatsApp 0086 15662723162

- Size: 106

- Place of Origin: Jinan,Shandong

- Brand Name: dingdian1

- Model Number: LT-6020

- Weight: 12000.000 kg

- :

- :

- :

- :

- :

- :

- :

- :

- :

- :

No. | Name | Brand |

1. | Laser Source | Germany IPG |

2. | Cutting head | Raytools/Precitec |

3. | Cutting system | Germany PA8000, Lantek/Gamma nesting software |

4. | Electrical control | Schneider |

5. | Pneumatic Control | SMC or Airtac |

6. | Linear guides | Taiwan Hiwin |

7. | Gear and rack | Taiwan YYC |

8. | AC servo motor and driver | Yaskawa |

9. | Reducer | France MOTOVARIO |

10. | Chiller | Tongfei |

11. | Chuck | Pneumatic chucks, automatic centering |

12. | Dust removal and filtration devices | Optional |

13. | Automatic feeding device | Optional |

No. | Item | Parameter |

1. | Maximum Travelling speed | 70m/min |

2. | Laser wavelength | 1070-1080 nm |

3. | Minimum cutting width | 0.2mm |

4. | Rated output power | 10--100% (100W-1000W) |

5. | X And Y axis positioning accuracy | ≤±0.03㎜ |

6. | Repeat positioning accuracy | ≤±0.02㎜ |

7. | Available cut pipe shape | Round tube, square tube, rectangular tube Oval tube, fan-shaped tube and so on |

8. | Acceleration | 1G |

9. | Oiling systems | Automatic oiling |

10. | Tail(Waste) length | 200-250mm |

11. | Effective length of cutting | 6000mm/8000mm/10000mm (customize dorder acceptable) |

12. | Size | 11*3.9*2.5m (Length * width * height) |

13. | Power | 35KW |

14. | G.W. | 10 Ton |

15. | Power supply | 380v50Hz ±10% |

16. | Red Positioning | Yes |

17. | Auxiliary gases | Oxygen, nitrogen, air |

18. | Supported file formats | IGS (Available PRO/E. UG, Solid works Photo) |

19. | Diameter | 20mm-200mm (can up to 320mm) |

20. | Laser tracking system | Automatic follow-up |